PREVIOUS: Acoustic Insulation Insulating is only one approach to avoid heat gain/loss. Passive cooling techniques were developed for the home, yet also apply to recreational vehicles. Cooling is enhanced through natural breezes or by fans that move the air; improved evaporation exposes the skin to dryer air as long as the humidity is not too… Continue reading Insulating Your RV: Passive Cooling

Tag: side door

How To Transform A Bed Into A Work Desk & More

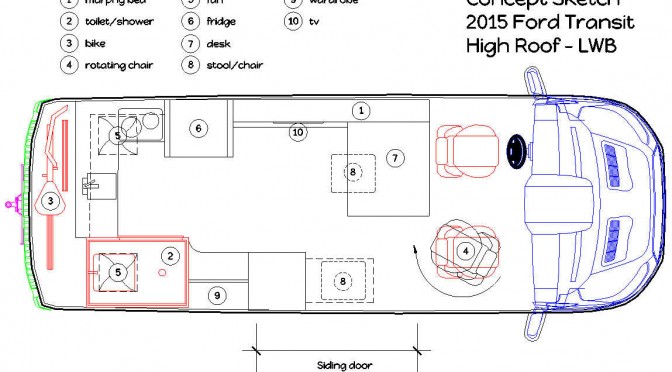

Going from bed to family room with TV and picture and finally to work desk, may be the ultimate task, that I set for myself, yet it may be the perfect solution for comfortable living in a small space, such as a converted cargo van. In finding the best layout for the new cargo van… Continue reading How To Transform A Bed Into A Work Desk & More

Monitor Console

Between the window and the side doors is a narrow strip of wall available to house a small console. It is the future location of the battery monitor and a reading light. With a narrow piece of wood, the length of the console, placed against the inside wall, the curve of the wall is transferred… Continue reading Monitor Console

Bed, Wall & Window

Before continuing with the other side of the van interior, it’s time to put the wall and window above the bed, back together again. Two issues remain: the battery cables and the solar controller cable need to be installed. The other is the decision I have to make, whether to go ahead with batting as… Continue reading Bed, Wall & Window

Wiring (2)

Continuing with the wiring of the van, gives me the opportunity to search for and order some of the materials, needed in the coming weeks. My list currently consists of wire connectors, heat shrink, 12V outlets and power inlet. I still haven’t found decent and affordable 12V LED light fixtures either. LED Lights Several… Continue reading Wiring (2)

Wiring

While working on the multi-use cabinet, I started with some of the wiring. Before I can continue building new cabinets, the majority of the electrical wiring has to be installed. Battery Monitor The monitor will be located on the wall next to the side doors and connected to the batteries with 4 small… Continue reading Wiring

Multi-Use Cabinet (8)

After my last post, I took a short brake, but now I’m refreshed and at it again. We are in the final stretch of the multi purpose cabinet and next time I hope to have it ready to install in the (cargo) van conversion. Meanwhile, to prevent any noise made by the cooktop cover while… Continue reading Multi-Use Cabinet (8)

Multi-Use Cabinet (7)

Previously I messed up one of the drawer bottoms of the cabinet that I’m making for my (cargo) van conversion. First redo that, then do the top surface with access to the cooktop. After all the major parts have been put together, only the hardware, the finishing and final installation in the van remains. … Continue reading Multi-Use Cabinet (7)

Multi-Use Cabinet (6)

A lot of time is spent on this multi purpose cabinet in pursuit of a high standard of finish. When it is ready and installed in the next two weeks, I will continue with the cargo van conversion. There’s the solar prep and walls & floors to be finished. Previously I installed a Romex… Continue reading Multi-Use Cabinet (6)

Multi-Use Cabinet (4)

Back Panel After the plywood core, the cherry frame and the decorations, I now turn to the back panel of the cabinet. In its up-position, it covers and protects the drawers section, while in the down-position it functions as a side table when sitting outside the van, with the side doors of the cargo… Continue reading Multi-Use Cabinet (4)